Brief Description:

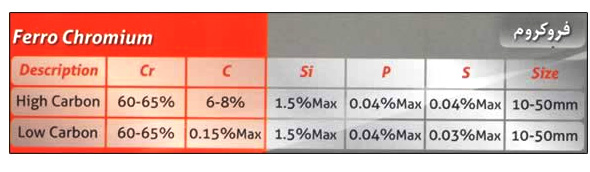

Ferrochrome (with the symbol FeCr) is one of the most important and widely used ferroalloys, primarily utilized in the steelmaking industry. Ferrochrome contains approximately 50 to 70 percent chromium and is produced using electric arc furnaces.

Ferrochrome can be categorized into three main types:

- Low-carbon Ferrochrome

- Medium-carbon Ferrochrome

- High-carbon Ferrochrome

Applications of Ferrochrome in the Casting Industry:

- Production of Stainless Steel: One of the primary applications of ferrochrome is in the production of stainless steel. This type of steel acquires its corrosion resistance and anti-rust properties due to its high chromium content.

- Improving Mechanical Properties: The addition of ferrochrome to alloys can enhance mechanical properties such as strength, hardness, and wear resistance.

- Production of Wear-Resistant Parts: In the casting industry, ferrochrome is used to manufacture components that require resistance to heat and wear. These parts may include engine components, industrial equipment, and cutting tools.

Overall, the addition of ferrochrome to the melt increases hardenability, depth of hardness, corrosion resistance, and wear resistance.